- Home

- Advanced Packaging

- Wafer-level Packaging Equipment Market Size, Future Growth and Forecast 2033

Wafer-level Packaging Equipment Market Size, Future Growth and Forecast 2033

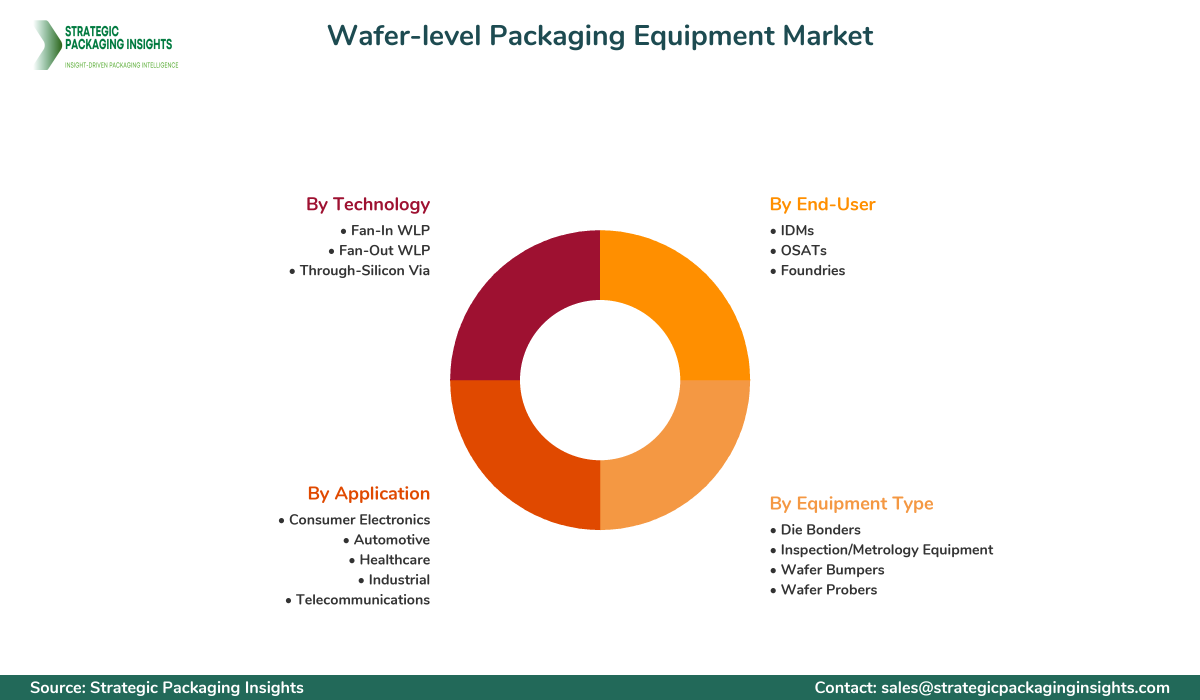

Wafer-level Packaging Equipment Market Segments - by Equipment Type (Die Bonders, Inspection/Metrology Equipment, Wafer Bumpers, Wafer Probers), Application (Consumer Electronics, Automotive, Healthcare, Industrial, Telecommunications), Technology (Fan-In WLP, Fan-Out WLP, Through-Silicon Via), and End-User (IDMs, OSATs, Foundries) - Market Dynamics, Growth Opportunities, Strategic Drivers, and PESTLE Outlook (2025–2033)

Wafer-level Packaging Equipment Market Outlook

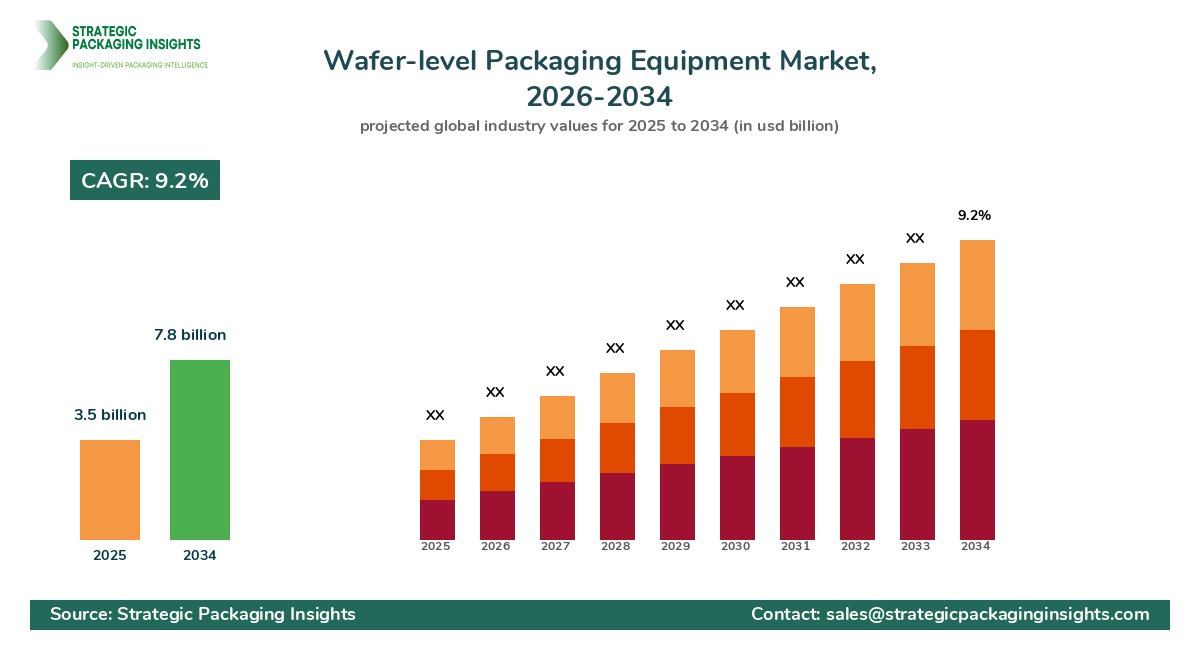

The wafer-level packaging equipment market was valued at $3.5 billion in 2024 and is projected to reach $7.8 billion by 2033, growing at a CAGR of 9.2% during the forecast period 2025–2033. This market is driven by the increasing demand for miniaturized electronic devices, which require Advanced Packaging solutions to enhance performance and reduce size. The proliferation of IoT devices and the expansion of 5G networks are also significant contributors to the market's growth, as they necessitate high-performance packaging solutions to support faster data transmission and processing speeds. Additionally, the automotive industry's shift towards electric and autonomous vehicles is creating a surge in demand for wafer-level packaging equipment, as these vehicles require sophisticated electronic components.

However, the market faces challenges such as high initial investment costs and the complexity of integrating new technologies into existing manufacturing processes. Regulatory constraints related to environmental standards and the need for skilled labor to operate advanced equipment also pose significant hurdles. Despite these challenges, the market holds substantial growth potential due to ongoing advancements in packaging technologies and the increasing adoption of AI and machine learning in manufacturing processes, which are expected to streamline operations and reduce costs over time.

Report Scope

| Attributes | Details |

| Report Title | Wafer-level Packaging Equipment Market Size, Future Growth and Forecast 2033 |

| Base Year | 2025 |

| Historic Data | 2018-2024 |

| Forecast Period | 2026-2034 |

| Number of Pages | 193 |

| Equipment Type | Die Bonders, Inspection/Metrology Equipment, Wafer Bumpers, Wafer Probers |

| Application | Consumer Electronics, Automotive, Healthcare, Industrial, Telecommunications |

| Technology | Fan-In WLP, Fan-Out WLP, Through-Silicon Via |

| End-User | IDMs, OSATs, Foundries |

| Customization Available | Yes* |

Opportunities & Threats

The wafer-level Packaging Equipment market presents numerous opportunities, particularly in the realm of technological advancements. The ongoing development of 3D packaging technologies and the integration of artificial intelligence in manufacturing processes are expected to drive significant growth. These advancements enable more efficient and precise packaging solutions, which are crucial for meeting the demands of next-generation electronic devices. Moreover, the increasing adoption of IoT devices across various industries is creating a substantial demand for advanced packaging solutions, as these devices require compact and efficient packaging to function effectively.

Another opportunity lies in the expansion of the semiconductor industry, driven by the growing demand for electronic devices and the proliferation of smart technologies. As the semiconductor industry continues to evolve, there is a rising need for advanced packaging solutions that can enhance the performance and reliability of semiconductor components. This trend is expected to drive the demand for wafer-level packaging equipment, as manufacturers seek to improve their packaging capabilities to meet the evolving needs of the industry.

Despite the promising opportunities, the market faces several threats that could hinder its growth. One of the primary challenges is the high cost of wafer-level packaging equipment, which can be a significant barrier for small and medium-sized enterprises. Additionally, the complexity of integrating new technologies into existing manufacturing processes can pose significant challenges, as it requires substantial investment in training and development. Furthermore, the market is subject to regulatory constraints related to environmental standards, which can increase operational costs and limit the adoption of new technologies.

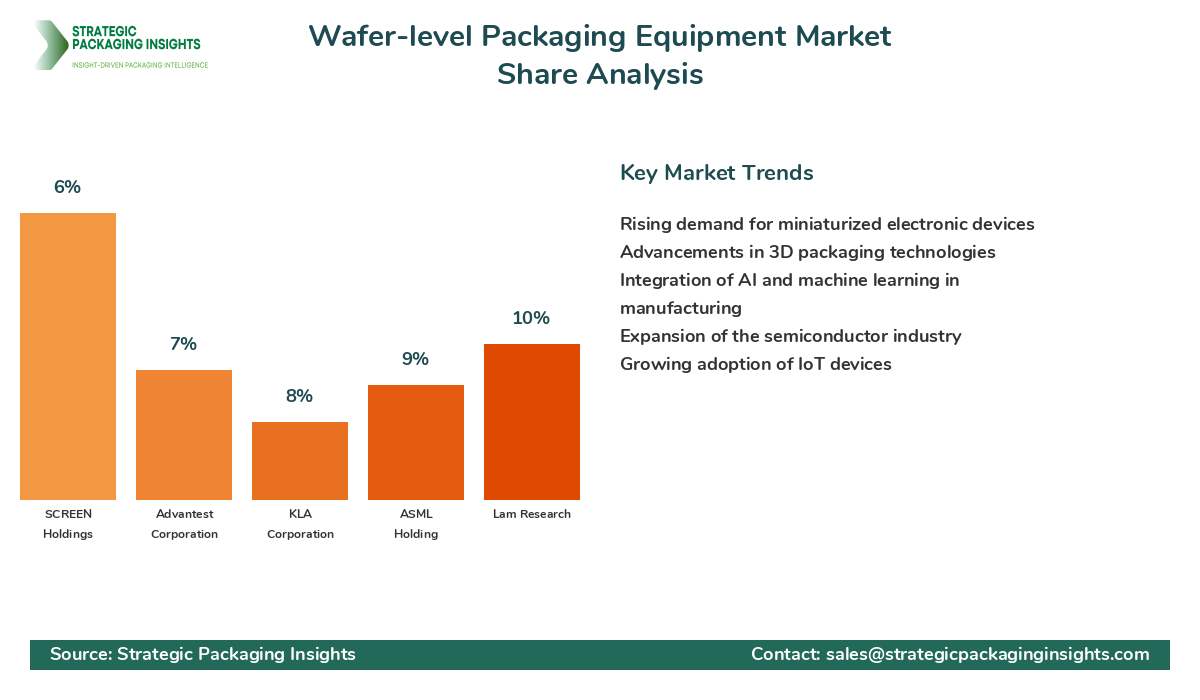

The wafer-level packaging equipment market is characterized by a highly competitive landscape, with several key players dominating the market. These companies are continuously investing in research and development to enhance their product offerings and maintain their competitive edge. The market is also witnessing a trend of strategic partnerships and collaborations, as companies seek to expand their market presence and leverage each other's strengths. The competitive landscape is further intensified by the entry of new players, who are introducing innovative solutions to capture market share.

Among the major players in the market, Applied Materials holds a significant share, driven by its extensive product portfolio and strong focus on innovation. The company is known for its advanced packaging solutions that cater to a wide range of applications, including consumer electronics, automotive, and telecommunications. Another key player, Tokyo Electron, is renowned for its cutting-edge technology and robust R&D capabilities, which have enabled it to maintain a strong market position. The company's strategic focus on expanding its global footprint and enhancing its product offerings has further strengthened its market presence.

Lam Research is another prominent player in the wafer-level packaging equipment market, known for its comprehensive range of solutions that address the diverse needs of the semiconductor industry. The company's commitment to innovation and customer-centric approach has enabled it to build a loyal customer base and achieve significant market share. Similarly, ASML Holding is a key player in the market, recognized for its advanced lithography solutions that are critical for wafer-level packaging processes. The company's strong focus on technological advancements and strategic partnerships has positioned it as a leader in the market.

Other notable players in the market include KLA Corporation, known for its inspection and metrology solutions, and Advantest Corporation, which specializes in semiconductor test equipment. These companies are continuously investing in R&D to enhance their product offerings and maintain their competitive edge. The market also includes several regional players who are leveraging their local expertise and customer relationships to capture market share. Overall, the wafer-level packaging equipment market is characterized by intense competition, with companies striving to innovate and differentiate their offerings to gain a competitive advantage.

Key Highlights Wafer-level Packaging Equipment Market

- Increasing demand for miniaturized electronic devices is driving market growth.

- Advancements in 3D packaging technologies are creating new opportunities.

- High initial investment costs pose a significant barrier for new entrants.

- Regulatory constraints related to environmental standards are impacting market dynamics.

- Strategic partnerships and collaborations are shaping the competitive landscape.

- Integration of AI and machine learning in manufacturing processes is enhancing efficiency.

- Expansion of the semiconductor industry is boosting demand for advanced packaging solutions.

- Complexity of integrating new technologies into existing processes is a major challenge.

- Growing adoption of IoT devices is driving demand for efficient packaging solutions.

- Entry of new players is intensifying competition in the market.

Top Countries Insights in Wafer-level Packaging Equipment

The United States is a leading market for wafer-level packaging equipment, with a market size of $1.2 billion and a CAGR of 10%. The country's strong semiconductor industry and focus on technological innovation are key growth drivers. Government initiatives to support advanced manufacturing and the presence of major industry players further bolster the market. However, regulatory challenges and high operational costs pose significant hurdles.

China is another major market, with a market size of $1 billion and a CAGR of 12%. The country's rapid industrialization and growing demand for electronic devices are driving market growth. Government policies supporting the semiconductor industry and investments in R&D are also contributing to the market's expansion. However, trade tensions and regulatory constraints remain challenges.

Japan, with a market size of $800 million and a CAGR of 9%, is a significant player in the wafer-level packaging equipment market. The country's strong focus on innovation and advanced manufacturing capabilities are key growth drivers. The presence of major industry players and government support for the semiconductor industry further enhance market prospects. However, an aging workforce and high operational costs pose challenges.

South Korea, with a market size of $700 million and a CAGR of 11%, is a key market for wafer-level packaging equipment. The country's robust semiconductor industry and focus on technological advancements are driving market growth. Government initiatives to support innovation and the presence of major industry players further bolster the market. However, geopolitical tensions and regulatory challenges remain concerns.

Germany, with a market size of $600 million and a CAGR of 8%, is a significant market for wafer-level packaging equipment. The country's strong focus on advanced manufacturing and innovation are key growth drivers. Government support for the semiconductor industry and the presence of major industry players further enhance market prospects. However, regulatory constraints and high operational costs pose challenges.

Value Chain Profitability Analysis

The wafer-level packaging equipment market's value chain involves several key stakeholders, including equipment manufacturers, technology providers, service providers, and end-users. Equipment manufacturers capture a significant share of the market value, driven by their ability to offer advanced and innovative solutions. These manufacturers typically operate on a high-margin business model, with profit margins ranging from 20% to 30%. Technology providers, who offer critical components and software solutions, also capture a substantial share of the market value, with profit margins ranging from 15% to 25%.

Service providers, including installation and maintenance services, play a crucial role in the value chain, capturing a moderate share of the market value. These providers typically operate on a lower-margin business model, with profit margins ranging from 10% to 15%. End-users, including semiconductor manufacturers and electronics companies, are the final stakeholders in the value chain, capturing the remaining share of the market value. These end-users typically operate on a low-margin business model, with profit margins ranging from 5% to 10%.

Digital transformation is reshaping the value chain, with technology providers and service providers capturing an increasing share of the market value. The integration of AI and machine learning in manufacturing processes is enhancing efficiency and reducing costs, enabling these stakeholders to capture higher profit margins. Additionally, the shift towards advanced packaging solutions is driving demand for innovative technologies and services, further increasing the market value captured by technology providers and service providers.

Evolving Market Dynamics (2018–2024) and Strategic Foresight (2025–2033)

The wafer-level packaging equipment market has undergone significant changes between 2018 and 2024, driven by technological advancements and evolving customer demands. During this period, the market experienced a CAGR of 7.5%, with a market size evolution from $2.5 billion to $3.5 billion. The segment distribution shifted towards advanced packaging solutions, with fan-out WLP and through-silicon via technologies gaining prominence. The regional contribution also changed, with Asia Pacific emerging as a key market, driven by the rapid industrialization and growing demand for electronic devices.

Looking ahead to the forecast period of 2025–2033, the market is expected to experience a higher CAGR of 9.2%, with a market size evolution from $3.5 billion to $7.8 billion. The segment distribution is expected to continue shifting towards advanced packaging solutions, with fan-in WLP and fan-out WLP technologies gaining further prominence. The regional contribution is also expected to change, with North America and Europe emerging as key markets, driven by the strong focus on technological innovation and advanced manufacturing capabilities.

Technological impact factors, such as the integration of AI and machine learning in manufacturing processes, are expected to play a crucial role in shaping the market dynamics. These technologies are expected to enhance efficiency and reduce costs, enabling companies to capture higher profit margins. Additionally, client demand transformations, driven by the increasing adoption of IoT devices and the proliferation of smart technologies, are expected to drive demand for advanced packaging solutions, further shaping the market dynamics.

Wafer-level Packaging Equipment Market Segments Insights

Equipment Type Analysis

The wafer-level packaging equipment market is segmented by equipment type, including die bonders, inspection/metrology equipment, wafer bumpers, and wafer probers. Die bonders are expected to witness significant growth, driven by the increasing demand for high-precision bonding solutions in advanced packaging processes. The integration of AI and machine learning in die bonding processes is enhancing efficiency and precision, further driving demand for these solutions. Inspection/metrology equipment is also expected to experience substantial growth, driven by the need for accurate and reliable inspection solutions in advanced packaging processes. The increasing complexity of packaging solutions is driving demand for advanced inspection technologies, further boosting the growth of this segment.

Wafer bumpers and wafer probers are also expected to witness significant growth, driven by the increasing demand for advanced packaging solutions in the semiconductor industry. The integration of AI and machine learning in wafer bumping and probing processes is enhancing efficiency and precision, further driving demand for these solutions. The increasing complexity of packaging solutions is driving demand for advanced wafer bumping and probing technologies, further boosting the growth of these segments. Overall, the equipment type segment is expected to witness significant growth, driven by the increasing demand for advanced packaging solutions and the integration of AI and machine learning in manufacturing processes.

Application Analysis

The wafer-level packaging equipment market is segmented by application, including consumer electronics, automotive, healthcare, industrial, and telecommunications. Consumer electronics is expected to be the largest application segment, driven by the increasing demand for miniaturized electronic devices and the proliferation of IoT devices. The integration of AI and machine learning in consumer electronics is enhancing performance and efficiency, further driving demand for advanced packaging solutions. The automotive industry is also expected to witness significant growth, driven by the increasing demand for advanced packaging solutions in electric and autonomous vehicles. The integration of AI and machine learning in automotive applications is enhancing performance and efficiency, further driving demand for advanced packaging solutions.

The healthcare industry is also expected to witness significant growth, driven by the increasing demand for advanced packaging solutions in medical devices and equipment. The integration of AI and machine learning in healthcare applications is enhancing performance and efficiency, further driving demand for advanced packaging solutions. The industrial and telecommunications industries are also expected to witness significant growth, driven by the increasing demand for advanced packaging solutions in industrial automation and telecommunications applications. Overall, the application segment is expected to witness significant growth, driven by the increasing demand for advanced packaging solutions and the integration of AI and machine learning in various applications.

Technology Analysis

The wafer-level packaging equipment market is segmented by technology, including fan-in WLP, fan-out WLP, and through-silicon via. Fan-in WLP is expected to witness significant growth, driven by the increasing demand for compact and efficient packaging solutions in consumer electronics and automotive applications. The integration of AI and machine learning in fan-in WLP processes is enhancing efficiency and precision, further driving demand for these solutions. Fan-out WLP is also expected to experience substantial growth, driven by the increasing demand for advanced packaging solutions in high-performance applications. The integration of AI and machine learning in fan-out WLP processes is enhancing efficiency and precision, further driving demand for these solutions.

Through-silicon via is also expected to witness significant growth, driven by the increasing demand for advanced packaging solutions in high-performance applications. The integration of AI and machine learning in through-silicon via processes is enhancing efficiency and precision, further driving demand for these solutions. The increasing complexity of packaging solutions is driving demand for advanced through-silicon via technologies, further boosting the growth of this segment. Overall, the technology segment is expected to witness significant growth, driven by the increasing demand for advanced packaging solutions and the integration of AI and machine learning in manufacturing processes.

End-User Analysis

The wafer-level packaging equipment market is segmented by end-user, including IDMs, OSATs, and foundries. IDMs are expected to be the largest end-user segment, driven by the increasing demand for advanced packaging solutions in semiconductor manufacturing. The integration of AI and machine learning in IDM processes is enhancing efficiency and precision, further driving demand for advanced packaging solutions. OSATs are also expected to witness significant growth, driven by the increasing demand for advanced packaging solutions in outsourced semiconductor assembly and test services. The integration of AI and machine learning in OSAT processes is enhancing efficiency and precision, further driving demand for advanced packaging solutions.

Foundries are also expected to witness significant growth, driven by the increasing demand for advanced packaging solutions in semiconductor manufacturing. The integration of AI and machine learning in foundry processes is enhancing efficiency and precision, further driving demand for advanced packaging solutions. The increasing complexity of packaging solutions is driving demand for advanced foundry technologies, further boosting the growth of this segment. Overall, the end-user segment is expected to witness significant growth, driven by the increasing demand for advanced packaging solutions and the integration of AI and machine learning in manufacturing processes.

Wafer-level Packaging Equipment Market Segments

The Wafer-level Packaging Equipment market has been segmented on the basis of

Equipment Type

- Die Bonders

- Inspection/Metrology Equipment

- Wafer Bumpers

- Wafer Probers

Application

- Consumer Electronics

- Automotive

- Healthcare

- Industrial

- Telecommunications

Technology

- Fan-In WLP

- Fan-Out WLP

- Through-Silicon Via

End-User

- IDMs

- OSATs

- Foundries

Primary Interview Insights

What are the key drivers of growth in the wafer-level packaging equipment market?

What challenges does the wafer-level packaging equipment market face?

How is digital transformation impacting the wafer-level packaging equipment market?

What role do strategic partnerships play in the wafer-level packaging equipment market?

Which regions are expected to witness significant growth in the wafer-level packaging equipment market?

Latest Reports

The export packaging market was valued at $150 billion in 2024 and is projected to reach $230 billion by 2033, growing at a CAGR of 4.8% during the forecast period 2025–2033.

The pallet wrapping packaging market was valued at $8.5 billion in 2024 and is projected to reach $12.3 billion by 2033, growing at a CAGR of 4.2% during the forecast period 2025–2033.

The stretch film packaging market was valued at $12.5 billion in 2024 and is projected to reach $20.3 billion by 2033, growing at a CAGR of 5.5% during the forecast period 2025–2033.

The shrink film packaging market was valued at $4.5 billion in 2024 and is projected to reach $7.8 billion by 2033, growing at a CAGR of 6.2% during the forecast period 2025–2033.

The connected packaging market was valued at $31.2 billion in 2024 and is projected to reach $82.1 billion by 2033, growing at a CAGR of 11.2% during the forecast period 2025–2033.

The active packaging market was valued at $18.5 billion in 2024 and is projected to reach $31.2 billion by 2033, growing at a CAGR of 6.2% during the forecast period 2025–2033.

The Intelligent Packaging market was valued at $18.5 billion in 2024 and is projected to reach $31.2 billion by 2033, growing at a CAGR of 6.2% during the forecast period 2025–2033.

The IoT-Enabled Packaging market was valued at $12.5 billion in 2024 and is projected to reach $35.7 billion by 2033, growing at a CAGR of 12.3% during the forecast period 2025–2033.

The NFC Packaging market was valued at $12.5 billion in 2024 and is projected to reach $35.7 billion by 2033, growing at a CAGR of 12.3% during the forecast period 2025–2033.

The RFID Packaging market was valued at $12.5 billion in 2024 and is projected to reach $28.7 billion by 2033, growing at a CAGR of 9.5% during the forecast period 2025–2033.

The sensor-enabled packaging market was valued at $18.5 billion in 2024 and is projected to reach $45.3 billion by 2033, growing at a CAGR of 10.5% during the forecast period 2025–2033.

The Temperature-Indicating Packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.8 billion by 2033, growing at a CAGR of 9.5% during the forecast period 2025–2033.

The Time-Temperature Indicator (TTI) Packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.5 billion by 2033, growing at a CAGR of 8.5% during the forecast period 2025–2033.

The Anti-Microbial Packaging market was valued at $10.5 billion in 2024 and is projected to reach $18.7 billion by 2033, growing at a CAGR of 6.5% during the forecast period 2025–2033.

The Oxygen Scavenger Packaging market was valued at $1.8 billion in 2024 and is projected to reach $3.2 billion by 2033, growing at a CAGR of 6.5% during the forecast period 2025–2033.

The moisture absorber packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.5 billion by 2033, growing at a CAGR of 8.5% during the forecast period 2025–2033.

The Ethylene Absorber Packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.5 billion by 2033, growing at a CAGR of 8.5% during the forecast period 2025–2033.

The Spoilage Indicator Packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.5 billion by 2033, growing at a CAGR of 8.5% during the forecast period 2025–2033.

The Tamper-Aware Smart Packaging market was valued at $2.5 billion in 2024 and is projected to reach $6.8 billion by 2033, growing at a CAGR of 11.5% during the forecast period 2025–2033.

The connected beverage packaging market was valued at $1.2 billion in 2024 and is projected to reach $3.5 billion by 2033, growing at a CAGR of 12.5% during the forecast period 2025–2033.

The QR-Code Packaging market was valued at $3.5 billion in 2024 and is projected to reach $9.8 billion by 2033, growing at a CAGR of 12.5% during the forecast period 2025–2033.

The AR-Enabled Packaging market was valued at $2.5 billion in 2024 and is projected to reach $12.8 billion by 2033, growing at a CAGR of 20.1% during the forecast period 2025–2033.

The Digital Printing Smart Packaging market was valued at $15.2 billion in 2024 and is projected to reach $28.7 billion by 2033, growing at a CAGR of 7.1% during the forecast period 2025–2033.

The blockchain-enabled packaging market was valued at $1.2 billion in 2024 and is projected to reach $5.8 billion by 2033, growing at a CAGR of 19.5% during the forecast period 2025–2033.

The Supply Chain Traceable Packaging market was valued at $12.5 billion in 2024 and is projected to reach $25.8 billion by 2033, growing at a CAGR of 8.2% during the forecast period 2025–2033.

The export packaging market was valued at $150 billion in 2024 and is projected to reach $230 billion by 2033, growing at a CAGR of 4.8% during the forecast period 2025–2033.

The pallet wrapping packaging market was valued at $8.5 billion in 2024 and is projected to reach $12.3 billion by 2033, growing at a CAGR of 4.2% during the forecast period 2025–2033.

The stretch film packaging market was valued at $12.5 billion in 2024 and is projected to reach $20.3 billion by 2033, growing at a CAGR of 5.5% during the forecast period 2025–2033.

The shrink film packaging market was valued at $4.5 billion in 2024 and is projected to reach $7.8 billion by 2033, growing at a CAGR of 6.2% during the forecast period 2025–2033.

The connected packaging market was valued at $31.2 billion in 2024 and is projected to reach $82.1 billion by 2033, growing at a CAGR of 11.2% during the forecast period 2025–2033.

The active packaging market was valued at $18.5 billion in 2024 and is projected to reach $31.2 billion by 2033, growing at a CAGR of 6.2% during the forecast period 2025–2033.

The Intelligent Packaging market was valued at $18.5 billion in 2024 and is projected to reach $31.2 billion by 2033, growing at a CAGR of 6.2% during the forecast period 2025–2033.

The IoT-Enabled Packaging market was valued at $12.5 billion in 2024 and is projected to reach $35.7 billion by 2033, growing at a CAGR of 12.3% during the forecast period 2025–2033.

The NFC Packaging market was valued at $12.5 billion in 2024 and is projected to reach $35.7 billion by 2033, growing at a CAGR of 12.3% during the forecast period 2025–2033.

The RFID Packaging market was valued at $12.5 billion in 2024 and is projected to reach $28.7 billion by 2033, growing at a CAGR of 9.5% during the forecast period 2025–2033.

The sensor-enabled packaging market was valued at $18.5 billion in 2024 and is projected to reach $45.3 billion by 2033, growing at a CAGR of 10.5% during the forecast period 2025–2033.

The Temperature-Indicating Packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.8 billion by 2033, growing at a CAGR of 9.5% during the forecast period 2025–2033.

The Time-Temperature Indicator (TTI) Packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.5 billion by 2033, growing at a CAGR of 8.5% during the forecast period 2025–2033.

The Anti-Microbial Packaging market was valued at $10.5 billion in 2024 and is projected to reach $18.7 billion by 2033, growing at a CAGR of 6.5% during the forecast period 2025–2033.

The Oxygen Scavenger Packaging market was valued at $1.8 billion in 2024 and is projected to reach $3.2 billion by 2033, growing at a CAGR of 6.5% during the forecast period 2025–2033.

The moisture absorber packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.5 billion by 2033, growing at a CAGR of 8.5% during the forecast period 2025–2033.

The Ethylene Absorber Packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.5 billion by 2033, growing at a CAGR of 8.5% during the forecast period 2025–2033.

The Spoilage Indicator Packaging market was valued at $1.2 billion in 2024 and is projected to reach $2.5 billion by 2033, growing at a CAGR of 8.5% during the forecast period 2025–2033.

The Tamper-Aware Smart Packaging market was valued at $2.5 billion in 2024 and is projected to reach $6.8 billion by 2033, growing at a CAGR of 11.5% during the forecast period 2025–2033.

The connected beverage packaging market was valued at $1.2 billion in 2024 and is projected to reach $3.5 billion by 2033, growing at a CAGR of 12.5% during the forecast period 2025–2033.

The QR-Code Packaging market was valued at $3.5 billion in 2024 and is projected to reach $9.8 billion by 2033, growing at a CAGR of 12.5% during the forecast period 2025–2033.

The AR-Enabled Packaging market was valued at $2.5 billion in 2024 and is projected to reach $12.8 billion by 2033, growing at a CAGR of 20.1% during the forecast period 2025–2033.

The Digital Printing Smart Packaging market was valued at $15.2 billion in 2024 and is projected to reach $28.7 billion by 2033, growing at a CAGR of 7.1% during the forecast period 2025–2033.

The blockchain-enabled packaging market was valued at $1.2 billion in 2024 and is projected to reach $5.8 billion by 2033, growing at a CAGR of 19.5% during the forecast period 2025–2033.

The Supply Chain Traceable Packaging market was valued at $12.5 billion in 2024 and is projected to reach $25.8 billion by 2033, growing at a CAGR of 8.2% during the forecast period 2025–2033.